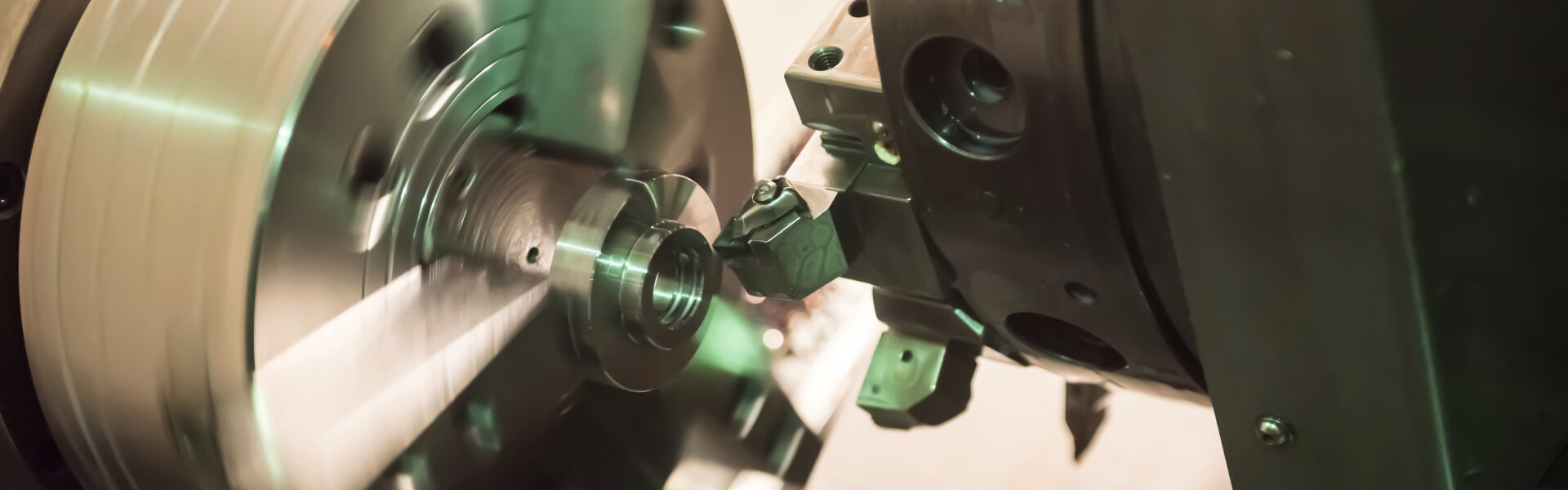

For excellence in work, we are equipped with the latest machines in our workshop where precision is the aim. Our technical expertise is instrumental in achieving the goal, which we have tie-up since the inception of MEGA MACHINERY. We have huge land and shed available to after almost all types of electrical, mechanical, and instrumental Machinery under one roof to facilitate our customers.

The equipment we manufacture are made with industry leading standards, designed using the latest CAD technology. We use the latest CAD / CAM softwares and Simulation software besides PV-Elite software used for equipment design and validation. The mechanical and process designing is carried out through our associate company

Backed by years and years of experience, elaborate discussions prior to manufacture, and highly experienced and skilled welders, fitters and riggers ensure that the products manufactured are of world class quality, in the shortest possible time without rework.

The use of latest cutting edge technology, continual updation of procedure qualification records, strict in-manufacture quality control ensures that the equipment manufactured are as per Quality Assurance Plan, and quality exceeding customer expectations. Mega Machinery has an in-house assembly facility or Basket trial, which includes speed runs at variable speed test, balancing , hydraulic test and alignment.

Mega Machinery is capable of working with various Materials of Construction such as:

* Hastelloy is a Trademark of Haynes International Inc.

** Monel, Inconel and Incoloy are Trademarks of Huntington Alloys Corp.

There are continuous technological advances taking place in welding and our customer centric philosophy warrants that we use the latest technique for manufacturing. We ensure that our welders are skilled with the latest technology and also as per ASME Section IX and / or EN ISO 3834-2. Our highly qualified team has particular expertise in working with reactive metals, high nickel alloys and stainless steels all of which are utilized for their resistance to corrosion and / or elevated temperature.

All welding procedures are tested, approved and certified to International Standards; ASME Section IX, EN ISO 3834 Part 2 and often additional and more stringent testing is conducted to comply with client’s specifications

Backed by years and years of experience, elaborate discussions prior to manufacture, and highly experienced and skilled welders, fitters and riggers ensure that the products manufactured are of world class quality, in the shortest possible time without rework.

The use of latest cutting edge technology, continual updation of procedure qualification records, strict in-manufacture quality control ensures that the equipment manufactured are as per Traveler / Quality Assurance Plan, and quality exceeding customer expectations. Mega has an in-house assembly facility or Basket trial, which includes speed runs at variable speed, balancing, hydrolic test and alignment.