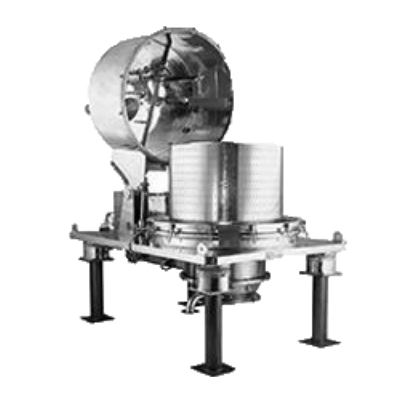

The process of Filtration is similar to other types of centrifuges, the difference being in the method of unloading the Solids. The Scraper cuts the Solid cake while the basket is rotating at a slow speed. The solids are discharged through openings provided in the Basket bottom and Bottom Base / Inertia Plate.

Mirror or Matt Finish can be provided with Grit 220 & Above on Contact & Non-Contact areas.

A.C. Inverter Drive shall be provided to vary the basket speed with built-in dynamic braking.

Provided in the centrifuge machine to clean the internals of the filtering centrifuge machine. CIP nozzles are placed at a different location to spray the wash liquid to all the surface which are not accessible from outside. During the cleaning process the centrifuge basket to be operated at a low speed to make cleaning more effective.

The centrifuge is mounted on inertia platform and suspended over four vibration-isolating dampers. This provides the following unique advantages:

The pneumatic cylinder will automatically get engaged with the lid as soon as basket starts rotating and gets disengaged only when it completely stops which will ensure that the lid can be opened only when the basket comes to a complete halt.

Shall be provided as a safety interlock for the Lid / Body. Unless the Lid / Body is closed motor cannot start and once the lid is opened motor power cuts off.

Will trip the Centrifuge during excessive vibration.

This system shall continuously monitor the vibration level of the machine. The system has two set point, one set point is for Alarm level and another set point is for trim level. The system also gives 4-20 amps output which can be hooked up to PLC.

The Nitrogen Inertisation is provided to the centrifuge basket chamber (casing) and to the bearing housing (sealing system). This system shall ensure that during the centrifuge operation the adequate nitrogen pressure is maintained within the basket chamber and bearing housing stuffing box chamber. Therefore, creating a Flame Proof System.

All the process cycles of centrifuge operations can be automated through a Programmable Logic Controller. The instruments mounted on the machine will communicate with the PLC system. The process cycles can be specifically designed and programmed to work according to the logic.

Heel Blowback System

The centrifuge machine is fitted with residual cake heel blowback system, which will remove the residual cake heel after the scraping operation.

It comprises concentric cones fabricated out of SS-316 sheet driven by 1 H.P. motor with frequency drive. This system facilitates uniform distribution of cake throughout the basket. Washing of the cake can also be performed through the same cone. The design also facilitates speedy extraction of mother liquor and wash liquid as well.

| Technical Specification | Centrifuge Model | ||||||

|---|---|---|---|---|---|---|---|

| Details | Unit | SM 36 BD | SM 36D BD | SM 48 BD | SM 48D BD | SM 60 BD | SM 60D BD |

| Basket Diameter | mm. | 915 | 915 | 1220 | 1220 | 1524 | 1524 |

| Basket Depth | mm. | 450 | 600 | 500 | 650 | 500 | 750 |

| Working Capacity under lip | Lts. | 160 | 220 | 300 | 400 | 500 | 750 |

| Basket Load (Max) | Kgs. | 200 | 275 | 375 | 500 | 625 | 930 |

| Max. Basket revolutions | rpm. | 1100 | 1100 | 1000 | 1000 | 900 | 850 |

| Centrifugal Force | G. | 619 | 619 | 682 | 682 | 691 | 616 |

| Filtration Area | sq.mts. | 1.29 | 1.72 | 1.91 | 2.49 | 2.39 | 3.59 |

| Motor Power | kW | 7.5 | 7.5 | 15 | 18.5 | 18.5 | 22 |

| Overall Dimensions | - | ||||||

| Length over Motor | mm. | 1780 | 1780 | 2150 | 2150 | 2500 | 2500 |

| Width | mm. | 1220 | 1220 | 1600 | 1600 | 2000 | 2000 |

| Operating Height | mm. | 1500 | 1700 | 2325 | 2500 | 2250 | 2500 |

| Weight of Machine with Motor | Kgs. | 3000 | 3100 | 4500 | 4750 | 7000 | 7500 |